SUMMARY: Oil and Gas pipelines are protected by various types of external coatings in conjunction with CP systems. Polyethylene is commonly used as the top coat in two or three layer systems. The existing two layer system found in the North American and Australian markets uses an adhesive that is mastic-based. It provides excellent corrosion resistant properties and has relatively low shear resistance in the adhesive layer, particularly at higher temperatures. The three layer system uses a copolymer adhesive to provide excellent shear properties and an epoxy layer which provides corrosion resistance. Both are excellent coatings when used in the proper environment. The major differences between the two systems are the mechanical properties at higher temperatures and the cost. The intention of this paper is to introduce a new system that bridges the gap in cost and performance between the two existing products. The new coating uses a hybrid adhesive which combines both the mastic and the copolymer functions, hence providing excellent corrosion resistance and adequate shear properties to withstand pipe movement and significantly reduce stockpiling and handling problems in high climate temperatures. The paper presents both the laboratory and plant production results and compares them to the properties of the other two existing coatings.

1. Introduction

Today’s pipelines in the oil, gas and water transportation industries worldwide are usually protected by external coatings in conjunction with cathodic protection systems. Pipe coating solution providers are offering various types of products tailored to the needs of their clients. Some of these common pipeline coating products include two-layer and three-layer coating systems that provide excellent anti-corrosion protection to pipes.

Two-layer systems refer to coatings that contain one layer of adhesive and another of polyethylene. Currently, the adhesives used in two-layer systems are either mastic-based or copolymers of polyethylene. Mastic-based adhesives, although being relatively inexpensive and providing good cathodic disbondment (C.D.) resistance, have low shear and peel strength values and are restricted to low temperature applications. Two-layer products based on copolymers have very good adhesion and shear resistance but generally poor cathodic disbondment resistance.

A three-layer system generally consists of an epoxy layer, a copolymer adhesive layer and a layer of polyethylene. This system can be operated at higher temperatures, however, due to the fact that an epoxy layer is required, it is more expensive with a more complex and critical application process.

The motivation for the product development introduced by this paper is to provide pipeline operators with a third alternative, one which joins the benefits of the two systems while eliminating most of their disadvantages. The development was designed and completed by Bredero Shaw – A ShawCor Company. Using a hybrid adhesive which combines the mastic and the copolymer functions, the product provides excellent corrosion resistance and adequate shear properties to withstand pipe movement and eliminate any stockpiling and handling problems in high climate temperatures. The paper presents both the laboratory and production results and compares them to the properties of the other two existing coatings.

2. The Product Development Approach

There are two types of adhesives used in the pipeline coating industry, mastic and copolymers. Mastic adhesives are mainly made from rubbers with the addition of modifiers. Just like rubber, they appear tacky and soft. Mastic adhesives can be broken further into two types: the asphalt based and the non-asphalt based. The asphalt based adhesives are inexpensive and provide excellent cathodic protection. The benefits and disadvantages of using mastic adhesives are outlined in Table 1.

Table 1: Advantages and Disadvantages of Using Mastic Adhesives in Pipeline Protection

Advantages

|

Disadvantages

|

| Lower manufacturing cost | Relatively low shear and peel resistance |

| Mostly amorphous | Lower operating temperature |

| Pressure sensitive | Poorer compression resistance (stock piling) |

| Forgiving to application temperature | Less resistance to soil stress |

| Forgiving to surface preparation | Limited to small diameter pipes (<600 mm or 26”) |

| Goof C.D resistance | |

| Excellent water repellents | |

| Easy to apply |

There are advantages and disadvantages of using copolymer adhesives in pipeline protection, which are outlined in Table 2. Copolymer adhesives, as previously mentioned, give outstanding shear and peel values, and can withstand high temperatures. However, they require more complex application procedures; they are higher in costs and have poor cathodic disbondment resistances without an epoxy under layer.

Table 2: Advantages and Disadvantages of Using Copolymer Adhesives in Pipeline Protection

Advantages

|

Disadvantages

|

| High shear and peel values | More complex to apply |

| Higher operating temperatures | Surface pre-heat is critical |

| Better compression resistance | Poor wetting characteristics |

| Excellent resistance to soil stress | Requires perfectly prepared and cleaned surface |

| More expensive | |

| Poor C.D. resistance without epoxy primer | |

| Sensitive to wet conditions and to cycling temperatures |

The hybrid adhesive was then applied in both laboratory and plant production settings using standard two layer extrusion equipment with minor modifications. After the application of the hybrid adhesive, an HDPE top layer was cross-head extruded. The HDPE was the same material that is normally used for standard two layer or three layer coating systems, having the typical material properties as shown in Table 3. Various materials and performance tests were conducted on both the new hybrid adhesive and the coated pipe samples as per standard AS/NZS 1518:2002 as well as other international pipe coating standards such as CSAZ245.21 and ISO 21809-4.Test data was then compared with typical values from standard 2 Layer Polyethylene (2LPE) and 3 Layer Polyethylene (3LPE) coating systems.

Figure 1: New hybrid adhesive brings together the desirable qualities of mastic-based and copolymer-based systems.

Table 3: Material properties of HDPE used as per AS/NZS 1518:2002

Property

|

Test Method

|

Acceptance Criteria

|

Typical Values

|

| Density | ASTM D1505 | 940 kg/m3 min. | 941 kg/m3 |

| Melt flow rate | ASTM D1238 190°C/2.16 kg | ≤ 0.60 g/10 min. | 0.3-0.45 g/10 min |

| Environmental stress-cracking at 100% Igepal concentration | ASTM D1693 Condition B(F50) | 900 hrs. | >1000 hrs. |

| Ultraviolet light resistance | AS1518 | 400% min. | >600% |

| Tensile strength at yield | AS1518 | 17 MPa min. | 18.5 MPa |

| Elongation to fracture | ASTM D638 Type IV | 400% min. | >600% |

| Resistance to thermal degradation | AS1518 | 30% max. variation of melt flow index | 10% |

| Resistance to splitting | AS1518 | 2 mm max. | 1.2 mm |

3. Performance Results and Discussions

Table 4 shows the material properties of the new hybrid adhesive versus typical mastic and copolymer adhesives used in standard 2LPE and 3LPE systems as per AS/NZS 1518:2002. It can be seen that the hybrid adhesive has a softening point of 110±10oC, which is slightly higher than that of standard mastic based adhesives used in 2LPE but much lower than that of copolymer adhesives for 3LPE. Adhesives with high softening points require more energy and time to coat the pipes, making pipe coating production less economical. On the other hand, adhesives with too low softening points restrict coatings to be used only for low temperature applications. The lap shear strength of the hybrid adhesive is significantly higher than the current mastic-based adhesives and similar to those of the copolymer adhesives.

Table 4: Material properties of new hybrid adhesive vs. mastic and copolymer as per AS/NZS 1518:2002

Property

|

Test Method

|

Acceptance Criteria

|

Mastic Adhesive

|

Hybrid Adhesive

|

Copolymer Adhesive (with Epoxy)

|

| Flow at 20±3oC | CSA Z245.21 | 5 mm max. | No Flow | No Flow | No Flow |

| Flow at 70oC | CSA Z245.21 | 20 mm max. | 9.8 mm | No Flow | No Flow |

| Softening point | AS1518 | 80°C min. | 96°C | 110±10°C | ~ 130-140°C |

| Coarse particle contamination | AS1518 | No retention on a 250 μm aperture sieve | Pass | Pass | Pass |

| Lap shear at 23°C @25.4 mm/min | AS1518 | 34 N/cm2 min. | 35 N/cm2 | 300 N/cm2 | 400 N/cm2 |

| Water absorption | AS1518 | 0.1 wt% max. | 0.04 wt% | 0.04 wt% | 0.1 wt% |

| Penetration | AS1518 | 5 mm max. | 4.3 mm | 0.85 mm | ~ 0.6 mm |

| Plasticity at 5oC | AS1518 | 180°bend at 5°C | Pass | Pass | Pass |

| Plasticity at -20oC | AS1518 | 180° bend at -20°C | Pass | Pass | Pass |

| Cathodic disbondment | AS4352 | Less than 12 mm at 22.5°C, 28 days | 6-11 mm | 7-9 mm | 4-9 mm |

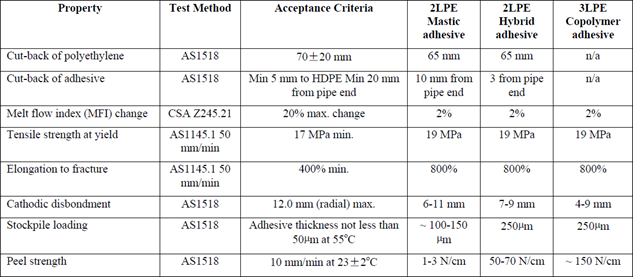

Table 5: Performance properties of the new hybrid 2LPE coating vs. standard 2LPE and 3LPE as per AS/NZS 1518:2002

Extensive testing was conducted at different temperatures to confirm that the new hybrid coating system has adequate shear properties to withstand pipe movement and sigficantly reduce any stockpiling and handling problems in high climate temperatures. As seen in Table 6, the lap shear strengths of the hybrid 2LPE system are significantly higher than that of the current mastic-based 2LPE and similar to those of the copolymer-based 3LPE at 23°C. At 70°C, the hybrid 2LPE exhibited quite similar lap shear strength values that would be otherwise achieved by standard mastic-based 2LPE systems at 23°C.

Table 6: Comparison of lap shear strength at different temperatures

Two additional types of peel adhesion tests were performed as per CSA Z245.21 and ISO21809-4 standards: the hanging weight peel test and the constant rate of peel (Instron peel test), with the testing results shown in Table 7. For the hanging weight peel test, a pipe coating system was rated as pass if its displacement was less than or equal to 10mm/min. The new hybrid 2LPE system passed the test with 300g, 2000g, 4000g and 5000g weights, while current mastic-based 2LPE would only meet 300g (as required by CSA Z245.21 for this type of coating). With the Instron peel test, the test values as well as the ways in which the systems failed were recorded. There are three modes of failure for a coating system: cohesive (separation occurs within the adhesive layer), adhesive-pipe (separation of adhesive layer completely from the steel surface of the pipe) and adhesive-topcoat (adhesive layer separation from topcoat but remains bonded to pipe). These peel tests showed the hybrid system to have much stronger peel strengths than the current mastic-based 2LPE and to fail cohesively.

Table 7: Comparison of peel adhesion strength by hanging weight testing and Instron peel testing

Table 8 shows the comparison of cathodic disbondment resistance of the new hybrid 2LPE pipe coating versus standard mastic-based 2LPE and standard 3LPE systems at different temperatures. Figure 2 shows the cathodic disbondment resistance testing setup at 65°C. At both room temperatures and 65°C the results obtained were comparable to the current mastic-based 2LPE products. Short-term cathodic disbondment testing at higher temperatures (70°C and 80°C) provided acceptable results.

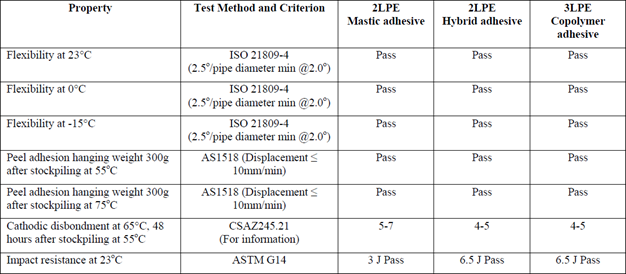

Table 9 shows the testing results of additional performance properties related to the ability of the new hybrid two-layer coating system for pipe handling and stockpile loading, including flexibility, peel adhesion after stockpiling, cathodic disbondment resistance after stockpiling and impact resistance. Flexibility refers to how much a material can be bended without rupturing. When coated pipes are laid into the ground, they are often bended to a certain degree to comform to the contour of the land. Therefore, it is important that any adhesive coated on the pipes are flexible enough to withstand the bend without cracking. Figure 3 shows good results of the flexibility testing as per ISO 21809-4. The results of both peel adhesion and cathodic disbondment resistance after stockpiling at 55oC and 75oC were also excellent. The impact resistance of the new hybrid 2LPE system was better than that of standard mastic-based 2LPE systems and about the same as 3LPE systems.

Table 8: Comparison of cathodic disbondment resistance at different temperatures

Table 9: Additional performance properties related to handling and stockpile loading

Figure 2 Cathodic disbondment resistance testing at 65°C

Figure 3 Samples of the new hybrid 2LPE coating after flexibility testing

4. Conclusions

A new two layer coating system has been developed to bring together the desirable qualities of mastic-based and copolymer-based systems while minimizing their disadvantages.

The new hybrid two layer coating system meets and exceeds the materials and performance property requirements of AS/NZS 1518:2002, CSAZ245.21, and ISO 21809-4 standards.

The new two layer coating system has better lap shear strength, peel adhesion strength, and impact resistance for temperatures up to 80°C than the current mastic-based 2LPE coating system and similar to that of the copolymer based 3LPE coating system offered in the North American and Australian markets. At both room temperatures and 65°C, the cathodic disbondment resistances of the new hybrid two layer coating system are comparable to the current mastic based 2LPE products. Short-term cathodic disbondment testing at higher temperatures (70°C and 80°C) also show acceptable results. These results demonstrate that the hybrid adhesive allows the achievement of excellent corrosion resistance and adequate shear properties to withstand pipe movement and eliminates any stockpiling and handling problems in high climate temperatures.

References:

Guan, S., P. Mayes, et. al. 2007. “Advanced Two Layer Polyethylene Coating Technology for Pipeline Protection”. Sydney, Australia.

http://www.brederoshaw.com/non_html/techpapers/BrederoShaw_TP_G_07.pdf

No comments:

Post a Comment