The fact that electric arc could operate was known for over a 100 years. The first ever underwater welding was carried out by British Admiralty – Dockyard for sealing leaking ship rivets below the water line. Underwater welding is an important tool for underwater fabrication works. In 1946, special waterproof electrodes were developed in Holland by ‘Van der Willingen’. In recent years the number of offshore structures including oil drilling rigs, pipelines, platforms are being installed significantly. Some of these structures will experience failures of its elements during normal usage and during unpredicted occurrences like storms, collisions. Any repair method will require the use of underwater welding.

Classification

Underwater welding can be classified as

1) Wet Welding

2) Dry Welding

In wet welding the welding is performed underwater, directly exposed to the wet environment. In dry welding, a dry chamber is created near the area to be welded and the welder does the job by staying inside the chamber.

WET WELDING

Wet Welding indicates that welding is performed underwater, directly exposed to the wet environment. A special electrode is used and welding is carried out manually just as one does in open air welding. The increased freedom of movement makes wet welding the most effective, efficient and economical method. Welding power supply is located on the surface with connection to the diver/welder via cables and hoses.

In wet welding MMA (manual metal arc welding) is used.

Power Supply used : DC

Polarity : -ve polarity

When DC is used with +ve polarity, electrolysis will take place and cause rapid deterioration of any metallic components in the electrode holder. For wet welding AC is not used on account of electrical safety and difficulty in maintaining an arc underwater.

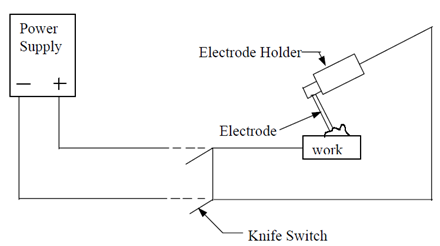

The power source should be a direct current machine rated at 300 or 400 amperes. Motor generator welding machines are most often used for underwater welding in the wet. The welding machine frame must be grounded to the ship. The welding circuit must include a positive type of switch, usually a knife switch operated on the surface and commanded by the welder-diver. The knife switch in the electrode circuit must be capable of breaking the full welding current and is used for safety reasons. The welding power should be connected to the electrode holder only during welding.

Direct current with electrode negative (straight polarity) is used. Special welding electrode holders with extra insulation against the water are used. The underwater welding electrode holder utilizes a twist type head for gripping the electrode. It accommodates two sizes of electrodes.

The electrode types used conform to AWS E6013 classification. The electrodes must be waterproofed. All connections must be thoroughly insulated so that the water cannot come in contact with the metal parts. If the insulation does leak, seawater will come in contact with the metal conductor and part of the current will leak away and will not be available at the arc. In addition, there will be rapid deterioration of the copper cable at the point of the leak.

Hyperbaric Welding (dry welding)

Hyperbaric welding is carried out in chamber sealed around the structure o be welded. The chamber is filled with a gas (commonly helium containing 0.5 bar of oxygen) at the prevailing pressure. The habitat is sealed onto the pipeline and filled with a breathable mixture of helium and oxygen, at or slightly above the ambient pressure at which the welding is to take place. This method produces high-quality weld joints that meet X-ray and code requirements. The gas tungsten arc welding process is employed for this process. The area under the floor of the Habitat is open to water. Thus the welding is done in the dry but at the hydrostatic pressure of the sea water surrounding the Habitat.

Risk Involved

There is a risk to the welder/diver of electric shock. Precautions include achieving adequate electrical insulation of the welding equipment, shutting off the electricity supply immediately the arc is extinguished, and limiting the open-circuit voltage of MMA (SMA) welding sets. Secondly, hydrogen and oxygen are produced by the arc in wet welding.

Precautions must be taken to avoid the build-up of pockets of gas, which are potentially explosive. The other main area of risk is to the life or health of the welder/diver from nitrogen introduced into the blood steam during exposure to air at increased pressure. Precautions include the provision of an emergency air or gas supply, stand-by divers, and decompression chambers to avoid nitrogen narcosis following rapid surfacing after saturation diving.

For the structures being welded by wet underwater welding, inspection following welding may be more difficult than for welds deposited in air. Assuring the integrity of such underwater welds may be more difficult, and there is a risk that defects may remain undetected.

Advantages and Disadvantages of Wet Welding

Advantages

Wet underwater MMA welding has now been widely used for many years in the repair of offshore platforms. The benefits of wet welding are: -

1) The versatility and low cost of wet welding makes this method highly desirable.

2) Other benefits include the speed. With which the operation is carried out.

3) It is less costly compared to dry welding.

4) The welder can reach portions of offshore structures that could not be welded using other methods.

5) No enclosures are needed and no time is lost building. Readily available standard welding machine and equipments are used. The equipment needed for mobilization of a wet welded job is minimal.

Disadvantages

Although wet welding is widely used for underwater fabrication works, it suffers from the following drawbacks: -

1) There is rapid quenching of the weld metal by the surrounding water. Although quenching increases the tensile strength of the weld, it decreases the ductility and impact strength of the weldment and increases porosity and hardness.

2) Hydrogen Embrittlement – Large amount of hydrogen is present in the weld region, resulting from the dissociation of the water vapour in the arc region. The H2 dissolves in the Heat Affected Zone (HAZ) and the weld metal, which causes Embrittlement, cracks and microscopic fissures. Cracks can grow and may result in catastrophic failure of the structure.

3) Another disadvantage is poor visibility. The welder some times is not able to weld properly.

Advantages and Disadvantages of Dry Welding

Advantages

1) Welder/Diver Safety – Welding is performed in a chamber, immune to ocean currents and marine animals. The warm, dry habitat is well illuminated and has its own environmental control system (ECS).

2) Good Quality Welds – This method has ability to produce welds of quality comparable to open air welds because water is no longer present to quench the weld and H2 level is much lower than wet welds.

3) Surface Monitoring – Joint preparation, pipe alignment, NDT inspection, etc. are monitored visually.

4) Non-Destructive Testing (NDT) – NDT is also facilitated by the dry habitat environment.

Disadvantages

1) The habitat welding requires large quantities of complex equipment and much support equipment on the surface. The chamber is extremely complex.

2) Cost of habitat welding is extremely high and increases with depth. Work depth has an effect on habitat welding. At greater depths, the arc constricts and corresponding higher voltages are required. The process is costly – a $ 80000 charge for a single weld job. One cannot use the same chamber for another job, if it is a different one.

Principle of operation of Wet Welding

The process of underwater wet welding takes in the following manner:

The work to be welded is connected to one side of an electric circuit, and a metal electrode to the other side. These two parts of the circuit are brought together, and then separated slightly. The electric current jumps the gap and causes a sustained spark (arc), which melts the bare metal, forming a weld pool. At the same time, the tip of electrode melts, and metal droplets are projected into the weld pool. During this operation, the flux covering the electrode melts to provide a shielding gas, which is used to stabilize the arc column and shield the transfer metal. The arc burns in a cavity formed inside the flux covering, which is designed to burn slower than the metal barrel of the electrode.

Developments in Under Water Welding

Wet welding has been used as an underwater welding technique for a long time and is still being used. With recent acceleration in the construction of offshore structures underwater welding has assumed increased importance. This has led to the development of alternative welding methods like friction welding, explosive welding, and stud welding. Sufficient literature is not available of these processes.

Scope for further developments

Wet MMA is still being used for underwater repairs, but the quality of wet welds is poor and are prone to hydrogen cracking. Dry Hyperbaric welds are better in quality than wet welds. Present trend is towards automation. THOR – 1 (TIG Hyperbaric Orbital Robot) is developed where diver performs pipefitting, installs the trac and orbital head on the pipe and the rest process is automated.

Developments of diverless Hyperbaric welding system is an even greater challenge calling for annexe developments like pipe preparation and aligning, automatic electrode and wire reel changing functions, using a robot arm installed. This is in testing stage in deep waters. Explosive and friction welding are also to be tested in deep waters.

Reference:

Joshi, Amit Mukund. –. “Underwater Welding”. Bombay: Indian Institute of Technology. Link: http://www.metalwebnews.com/howto/underwater-welding/underwater-welding.pdf